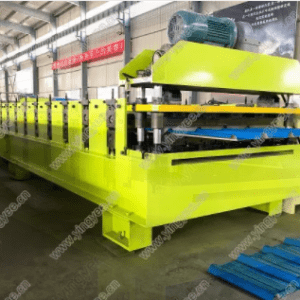

irin IBR orule dì eerun lara ẹrọ

Apejuwe kukuru:

WIlana gbigbe:

Ẹya ara:

Afowoyi - alakojopo x1 ṣeto l

adijositabulu igbewọle ohun elo x1 ṣeto l

Akọkọ eerun akoso ẹrọ pẹlu chromed awo x1 ṣeto

Epo eefun gige eto x1 ṣeto l

Epo eefun ibudo x1 ṣeto l

PLC Iṣakoso eto x1 ṣeto l

Ṣiṣe-jade x1 ṣeto

Imọ paramita

| Afọwọṣe Decoiler | 1: Iwọn ti o pọju ti ohun elo aise: 1300mm2: Agbara: 5000kgs3: Iwọn inu ti okun: 450-600mm |

| Eerun lara ẹrọ | 1.Matching material: PPGI/GI/Aluminium2.Material sisanra:0.2-1mm3.Power:7.5kw4.Forming speed:0-30m/min5.The width of the plates: according to the draws6.input leveling equipment: adaptable as photos .7.Roll stations:228.Shaft Material and diameter:materialis45#steel ¢80mm,9.Furada: 10m±1.5mm10.Way ti wakọ: pq pẹlu motor 11.Controlling eto:PLC 12.Voltage, Frequency, Phase: da lori ibeere alabara 13.Material of forming rollers:45#steel heat treatment and chromed 14Materialofcutterblade:Cr12mouldsteelwith quenched treatmentHRC58-62 15. Side awo: irin awo pẹlu Chromed. |

| Ige (itọnisọna eefun) | 1. Gbigbe gige: Ẹrọ akọkọ duro laifọwọyi ati lẹhinna gige.Lẹhin gige, ẹrọ akọkọ yoo bẹrẹ laifọwọyi.2.Material of blade: Cr12 mold steel with quenchedtreatment58-62℃3.Length: Aifọwọyi ipari wiwọn4.Tolerance ti ipari: 10+/- 1.5mm |

Aworan

Fi ifiranṣẹ rẹ ranṣẹ si wa:

Kọ ifiranṣẹ rẹ nibi ki o si fi si wa

坐前面带出料.jpg)

坐前面带出料-300x225.jpg)

左前面带出料斜上-300x225.jpg)

左后面斜上-300x225.jpg)

右后面斜上-300x225.jpg)

成型产品效果-300x225.jpg)

切断部分电动切断-2-300x225.jpg)

前面带出料-300x225.jpg)

后面斜上-300x224.jpg)

坐前面带出料-300x225.jpg)

左前面带出料斜上-300x225.jpg)

后面斜上-300x224.jpg)

成型产品效果-300x225.jpg)

切断部分电动切断-2-300x225.jpg)

前面带出料-300x225.jpg)

右后面斜上-300x225.jpg)

左后面斜上-300x225.jpg)